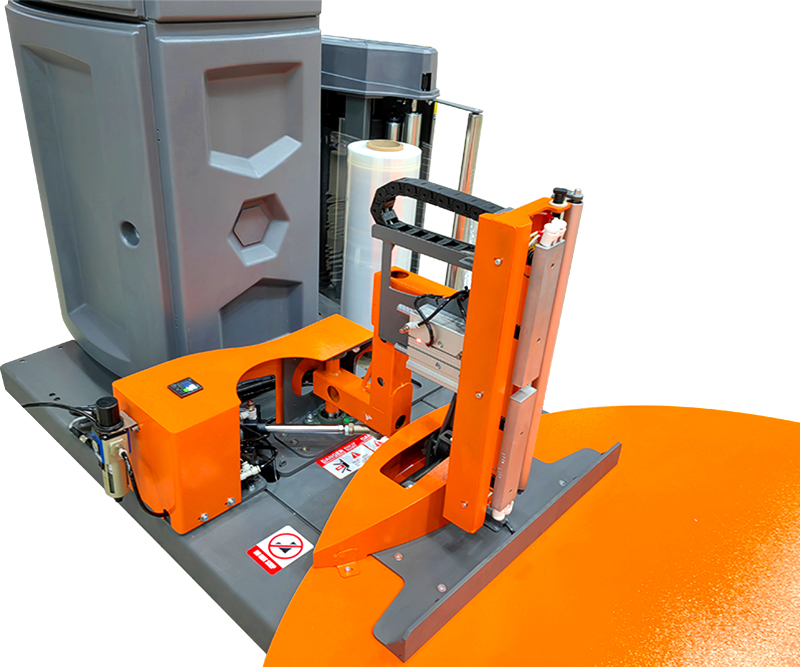

Achieves up to 380% pre-stretch rate, maximizing film usage.

Ensures fixed-point wrapping with consistent film release.

Offers a quantitative use film system, reducing waste and optimizing material consumption.

High Pre-Stretch Rate for Film Savings

Fully automated cutting and clamping eliminate the need for manual intervention.

Welded-type system ensures no film tails after wrapping, enhancing the final package appearance.

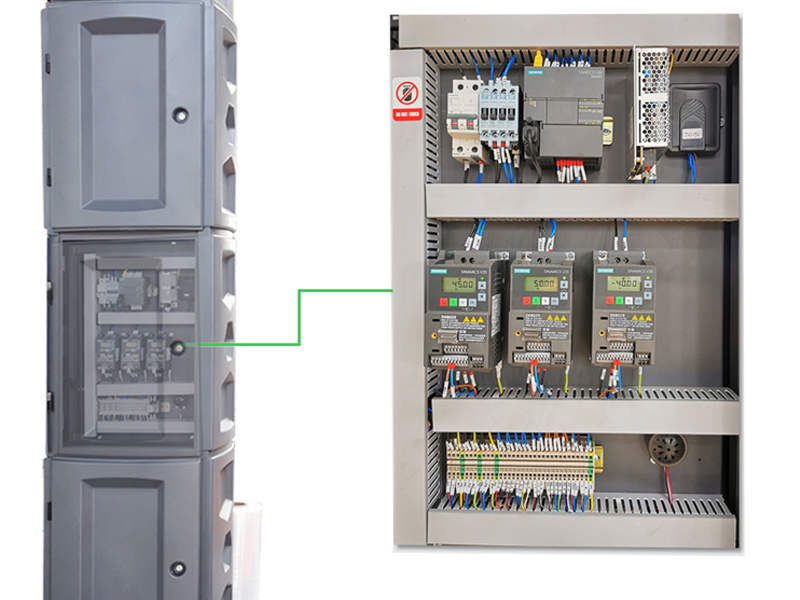

Our machines incorporate premium SIEMENS electrical components for durability and reliability. High-quality electrical systems reduce downtime and simplify troubleshooting, ensuring your operations run smoothly.

Set turntable speed, up/down speed, and film carriage speed.

Configure six customizable wrapping models for different pallet requirements, minimizing setup time.

The intuitive IoT touchscreen simplifies operation by allowing users to:

Food and Beverage

Electronics and Electrical Appliances

Ceramics, Chemicals, and Construction Materials

The Automatic Stretch Film Wrapper Pneumatic is versatile, catering to various industries such as:

With customizable settings, our Spinny Pallet Wrappers adapt to diverse material, size, and shape requirements, ensuring consistent results across applications.

Consistent Performance: Delivers uniform wrapping strength across all loads.

Cost-Effective: Offers factory pricing with robust construction, including a solid steel chassis and 20mm-thick plates.

Labor Savings: Reduces the need for manual handling during the wrapping process.

If you're looking for an Automatic Stretch Film Wrapper Pneumatic, we provide cutting-edge solutions designed to maximize efficiency and minimize manual labor. With Smart Wasp Pallet Wrappers, you can expect durable, intelligent machines capable of meeting the diverse needs of various industries. From automated film cutting to advanced IoT controls, our equipment is engineered for reliability and cost-effectiveness.

For reliable and efficient Automatic Stretch Film Wrapper Pneumatic solutions, choose the Smart Wasp Pallet Wrapper. With advanced technology and industry-leading features, our machines ensure superior performance and durability, streamlining your operations.

| Model | Smart Wasp X100p | Spare Parts | Brand | ||||||||||

| Feature | Main Products | Inverter | SIEMENS | ||||||||||

| Maximum wrapping speed | 15-25 loads/hour | Photoeletric sensor | SICK(Germany) | ||||||||||

| Max Wrapping Height & Weight | 2200mm / 2000KG | PLC | SIEMENS(Germany) | ||||||||||

| Turntable Speed | 0-13RPM(Adjustable) | Travel Switch | OMRON(Japan) | ||||||||||

| Turntable Size | 1650mm | Motor | GPG(Taiwan) | ||||||||||

| Turntable Drive | 0.75PH Chain Drive | Relay | OMRON(Japan) | ||||||||||

| Clmap and Cut Film | Automatic | Reducer | GPG | ||||||||||

| Machine Size | L:2800mm W:1650mm H:3250mm | Position switch | SICK(Germany) | ||||||||||

| Machine Weight | 800KG | Touch screen | X-LINE/SIEMENS | ||||||||||

| Standard Pre-Stretch | 300% pre-stretch | Contactor | SIEMENS | ||||||||||

| Film Capacity | 250mm Diameter | ||||||||||||

| Standard Film Width | 500mm | ||||||||||||

| Film Delivery System | Power Pre -Stretch | Special Process | Introduction | ||||||||||

| Packing Force | Changeable | Frame | Steel+ABS | ||||||||||

| Intelligent-Sensor | Standard | Printing | Metallic Paint | ||||||||||

| Rope Grip System | Optional | Fall-proof | Inside Safety Belt | ||||||||||

| Safety Device | CE standard | Cutting | Laser | ||||||||||

| Alarm System | Have | Turntable Roller | Double Nylon Roller | ||||||||||

| Top Pressure | Motor Drive/600-2200mm press height | Up&Down Drive | Belt | ||||||||||

| Ramp: | optional | Up&Down Guideway | Double Balance Device | ||||||||||

FAQ

1.What's mast height of machine?

X100p pallet wrapping machine mast height is 2650mm ,and the max packing height is 2000mm, if you pallet's size over 2000mm, may need choose mast height 3600mm, the max packing height 3000mm

2.How to choose control system?

All use Siemens control system.Top brand spare parts ensure a longer machine lifespan.

3.What's turntable size ?

The standard turntable size is 1800mm. 1650 mm and 2000mm turntable optional

4.What's temperature can be use ?

Standard machine need > 0 degree

If <0 degree ,need tell us ,we need use a special motor for machine

5.What's the thickness of turntable steel and use what cut the steel?

Turntable steel 10mm ,and use water cutting teachnology,do not use laser cutting.

6.What's max weight can be use?

Our standard pallet stretch wrapper max load weight 2000KG ,above 2000KG we need change to steel roller under the turntable ,standard machine use plastic roller .

7.Ramp and weighing scale weather can provide

Yes,ramp and weighing scale is optional.